1 kg pellets

$50

Weight: 1 kg

Extruder temperature: 220-250˚ C

Build plate temperature: 50-70°C

Chamber temperature: Not required

5 kg pellets

$210

Weight: 5 kg

Extruder temperature: 220-250˚ C

Build plate temperature: 50-70°C

Chamber temperature: Not required

10 kg pellets

$375

Weight: 10 kg

Extruder temperature: 220-250˚ C

Build plate temperature: 50-70°C

Chamber temperature: Not required

AquaSys GP, AquaSys 120, Polypropylene

Because it’s partially composed of water-soluble material, Caverna ST may absorb moisture. Always store your filament in the resealable bag it arrives in and ensure that it is sealed after each use.

The metal bag should contain a desiccant. Don’t throw it out, and consider adding another desiccant if available for additional moisture protection.

Never expose the desiccant to moisture. Otherwise, you’ll need to replace it.

If Caverna ST absorbs moisture while in storage, print quality will decrease. If that happens, dry at 70°C in a low-humidity environment for three to four hours.

Never store Caverna ST on the back or side of the printer.

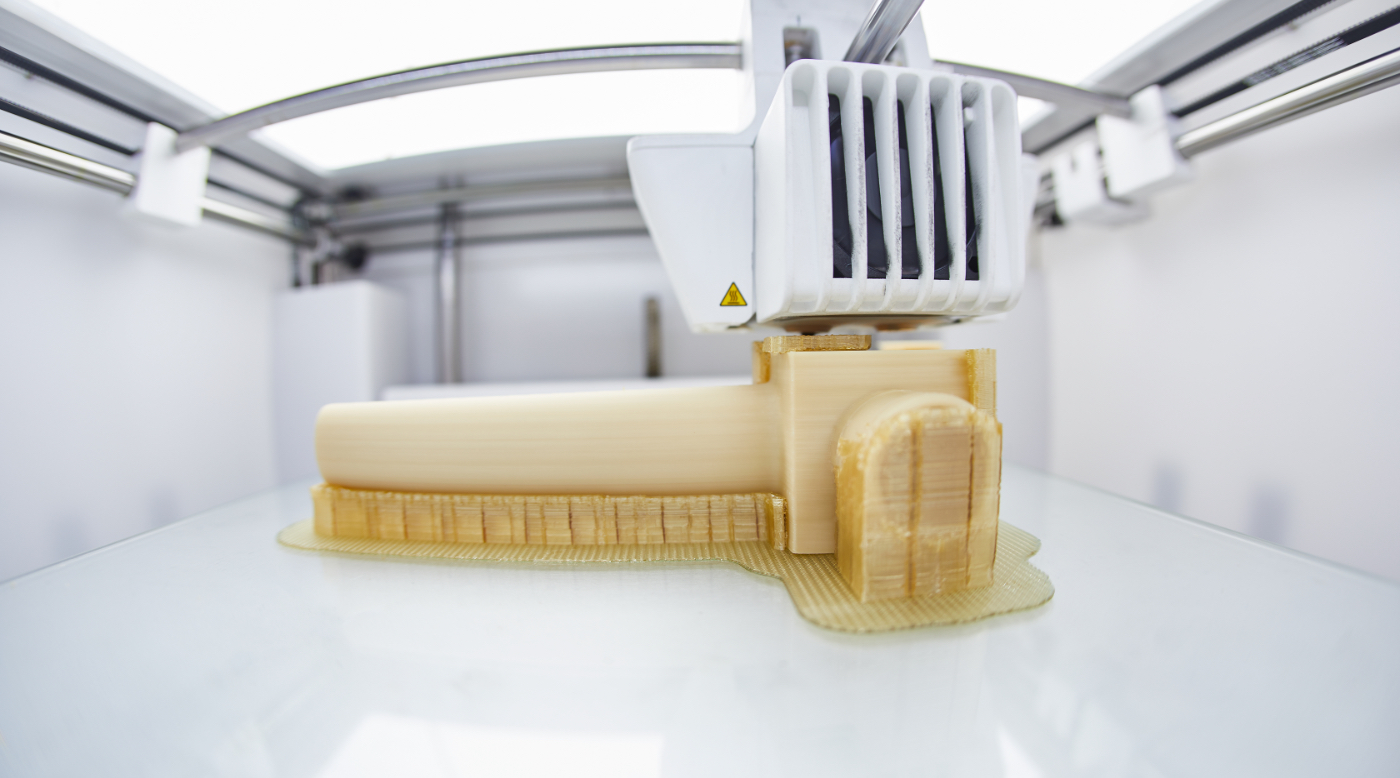

- Nozzle temperature: 220-250°C

- Build plate temperature: 50-70°C

- Chamber temperature: No heated chamber necessary.

50-70°C in agitated water, 50% of the mass is soluble content

The statements, technical information and recommendations contained herein are believed to be accurate as of the date hereof. Since the conditions and methods of use of the product and of the information referred to herein are beyond our control, Infinite Material Solutions, LLC. Expressly disclaims any and all liability as to any results obtained or arising from any use of the product or reliance on such information: NO WARRANTY OF FITNESS FOR ANY PARTICULAR PURPOSE, WARRANTY OF MERCHANTABILITY OR ANY OTHER WARRANTY, EXPRESSED OR IMPLIED, IS MADE CONCERNING THE GOODS DESCRIBED OR THE INFORMATION PROVIDED HEREIN. The information provided herein relates only to the specific product described and may not be applicable when such product is used in combination with other materials or in any process. The user should thoroughly test any application before commercialization. Nothing contained herein constitutes a license to practice under any patent and it should not be construed as an inducement to infringe any patent and the user.